In the realm of industrial power generation, stability and performance are critical. Generators must run smoothly and reliably under demanding conditions, whether providing backup during outages or operating continuously in remote locations. One essential component that directly affects a generator’s performance and durability is the engine mount. Though often overlooked, engine mounts are foundational to maintaining the structural integrity, vibration control, and alignment of industrial generators.

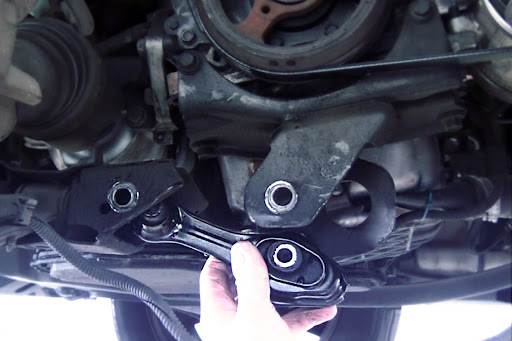

Engine mounts serve to secure the generator engine to its frame while absorbing vibration and mitigating operational stress. Choosing the right engine mount is vital for ensuring long-term stability and reducing the risk of wear, fatigue, and failure in connected systems. Reputable suppliers offer a variety of engine mount types tailored for different industrial applications, helping ensure your generator operates smoothly under load.

This article explores how proper engine mount solutions support generator stability and what to consider when selecting and maintaining them in industrial environments.

Why Engine Mounts Matter for Generators

Industrial generators are heavy-duty machines that operate in high-vibration environments. The engine produces continuous rotational force, which can create significant vibration and noise. If not properly managed, this can lead to structural fatigue, alignment issues, and even failure of essential components such as couplings, housings, or electrical systems.

Engine mounts play a crucial role by:

- Dampening vibration: Preventing the transfer of engine vibration to the frame and nearby equipment.

- Maintaining alignment: Ensuring proper coupling between the engine and generator head, which improves efficiency and reduces wear.

- Extending lifespan: Reducing mechanical stress across the system, contributing to longer equipment life and fewer service interruptions.

- Enhancing safety: Preventing excessive engine movement that could damage critical infrastructure or create hazards in industrial settings.

Types of Engine Mounts for Generator Applications

There are several types of mounts used in industrial generators, each with specific design benefits depending on the application:

- Rubber isolator mounts: Ideal for light-to-medium duty applications, offering cost-effective vibration dampening.

- Spring mounts: Suitable for environments with significant vibration or where isolating low-frequency vibrations is critical.

- Hydraulic mounts: Provide excellent dampening and are used in high-performance applications where precise control is needed.

- Metal-to-rubber bonded mounts: These combine strength and flexibility, commonly used in rugged environments requiring extra durability.

The selection of a proper engine mount depends on factors such as engine weight, operating conditions, frequency of use, and environmental exposure.

Signs of Failing Engine Mounts

Detecting early signs of engine mount failure can prevent costly breakdowns. Common indicators include:

- Increased vibration: A sudden rise in noise or vibration levels during operation may suggest worn mounts.

- Visible wear or cracking: Physical damage to the rubber or metal components of the mount.

- Misalignment: Shifting of the engine position or trouble maintaining proper coupling alignment.

- Excessive engine movement: Engine sway during startup or shutdown that appears abnormal.

Routine inspections should be part of your maintenance schedule to identify these signs early.

Best Practices for Installation and Maintenance

Installing engine mounts correctly is just as important as selecting the right type. Improper installation can lead to uneven load distribution, premature wear, and ineffective vibration control. Here are some best practices:

- Follow Manufacturer Specifications: Always use the recommended torque settings and installation procedures.

- Use Shims or Leveling Tools: Ensure mounts are level and evenly support the engine weight.

- Check Bolt Tension Regularly: Loose bolts can cause movement and vibration. Recheck tension after initial use.

- Protect from Oil and Chemicals: Exposure can degrade rubber components. Use protective covers or deflectors where necessary.

- Replace in Pairs or Sets: To maintain balance and alignment, replace all mounts at once rather than one at a time.

Choosing Quality Engine Mount Solutions

Investing in quality mounts from trusted sources pays off through reduced maintenance needs, improved generator performance, and longer service life. Industrial engine mounts should be made from high-grade materials capable of handling load, vibration, temperature, and chemical exposure common to power generation environments.

Before purchasing, evaluate:

- Load capacity and deflection rating

- Material composition and resistance to wear

- Compatibility with your specific generator make and model

- Customer reviews and technical support from the supplier

Reliable suppliers often provide detailed specifications and assistance in choosing the best fit for your application.

Conclusion

Engine mount solutions are a small but crucial part of ensuring industrial generator stability. By selecting the appropriate type, maintaining them regularly, and sourcing quality parts, operators can achieve better performance, reduced vibration, and increased system longevity. In demanding industrial settings, this translates to fewer breakdowns, better energy efficiency, and overall improved reliability of your power generation system.

Whether you’re upgrading an existing setup or commissioning a new generator, don’t underestimate the importance of choosing the right engine mount—it’s the foundation that keeps your system running smoothly.