In the competitive landscape of manufacturing and packaging, visual appeal plays as crucial a role as functionality. From premium packaging to decorative finishes on printed materials, hot stamping has long been a preferred method for enhancing product presentation. Over time, this technology has advanced significantly, and the development of automatic hot stamping machines has transformed the process into a more efficient, precise, and versatile solution.

What is an Automatic Hot Stamping Machine?

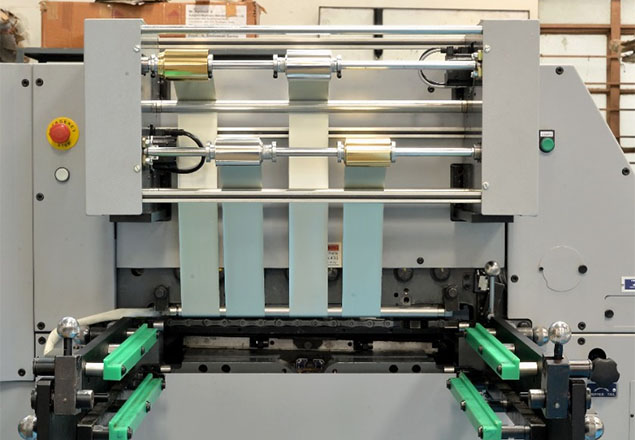

An automatic hot stamping machine is an industrial tool designed to transfer metallic or pigmented foils onto various surfaces using heat and pressure. Unlike traditional manual systems, these machines operate with a high degree of automation, reducing human intervention while increasing output accuracy and speed. Whether for adding metallic logos on packaging, decorative patterns on books, or serial numbers on labels, the automatic design ensures consistency and quality in every application.

Advantages of Automatic Hot Stamping Machines

Precision and Consistency

Automation allows for exact pressure, temperature, and positioning during the stamping process. This precision ensures every stamped design looks identical, regardless of the production volume, eliminating inconsistencies often found in manual operations.

Efficiency and Speed

One of the biggest strengths of automatic hot stamping machines is their ability to handle large production runs with minimal downtime. Automated feeding, alignment, and foil handling systems accelerate production while reducing errors.

Versatility Across Materials

These machines can stamp on a wide range of substrates, including paperboard, plastics, textiles, leather, and even certain metals. This adaptability makes them suitable for diverse industries such as packaging, publishing, fashion, and electronics.

Enhanced Aesthetic Appeal

Hot stamping adds a premium look and feel to products. From glossy metallic foils to subtle matte finishes, the technology creates a high-quality, luxurious impression that appeals strongly to consumers.

Key Applications of Automatic Hot Stamping

Packaging Industry

In packaging, hot stamping is widely used to enhance brand recognition. Logos, labels, and decorative patterns can be stamped with foils that make the product stand out on shelves. Luxury goods packaging especially benefits from metallic finishes that convey elegance and exclusivity.

Publishing and Printing

Book covers, certificates, and invitations often use hot stamping to highlight important text or designs. Automatic systems make it possible to produce these embellishments quickly and consistently, regardless of volume.

Fashion and Textiles

Leather goods, apparel labels, and accessories frequently incorporate hot stamping for branding or decorative details. Automation ensures that every piece meets the same quality standard, important for high-end fashion products.

Electronics and Industrial Applications

Beyond decorative purposes, hot stamping is also used functionally, such as adding serial numbers, barcodes, or safety markings on electronic components and machinery. The durability of the stamped markings ensures longevity in demanding conditions.

Comparing Manual and Automatic Systems

Manual hot stamping is suitable for small-scale or craft production but falls short in high-volume manufacturing. Automatic hot stamping machines, by contrast, offer:

- Greater speed for mass production.

- Consistent quality across thousands of units.

- Reduced labor costs due to minimized manual intervention.

- Expanded design capabilities for complex or detailed patterns.

For companies aiming to scale production while maintaining quality, automation becomes the natural choice.

Technology and Features in Modern Systems

Digital Controls

Today’s machines often come with programmable digital interfaces, allowing operators to adjust temperature, pressure, and foil feed rates with precision. This reduces setup time and enhances flexibility when switching between projects.

Automated Feeding and Alignment

Advanced feeding systems ensure materials are aligned correctly before stamping. Automated alignment reduces waste and improves output quality, particularly in large-scale production runs.

Multi-Station Capabilities

Some machines can perform multiple stamping operations in a single pass, combining different foils, embossing, or textures for more intricate designs without additional handling.

Safety and Energy Efficiency

With features such as automatic shutoff, heat control, and eco-friendly power consumption, modern hot stamping systems balance safety with sustainability.

The Role of Sustainability in Hot Stamping

Sustainability has become an industry priority, and hot stamping technology has adapted accordingly. Foils used in the process are typically thin and leave minimal waste, while precision cutting ensures maximum utilization of materials. Additionally, the durability of stamped finishes reduces the need for secondary treatments, lowering overall environmental impact.

Considerations When Choosing an Automatic Hot Stamping Machine

Before investing in a system, manufacturers should evaluate several factors:

- Material compatibility: Can the machine handle all substrates needed for production?

- Foil options: Does it support a variety of foils for different finishes and textures?

- Production capacity: Is the system suited for current and future demand?

- Ease of operation: Are the controls intuitive and user-friendly?

- Maintenance requirements: How durable is the system under continuous operation?

Making informed choices ensures long-term productivity and cost-effectiveness.

Future Trends in Hot Stamping Technology

The future of automatic hot stamping lies in the integration of smart technology, artificial intelligence, and connected monitoring systems. Machines may soon be capable of predictive maintenance, self-adjusting settings based on material input, and energy optimization. These advancements will make stamping even more efficient and sustainable, while expanding creative possibilities for designers and manufacturers.

Conclusion

Automatic hot stamping machines have redefined how industries enhance product design and functionality. With their ability to combine speed, precision, and versatility, they serve as essential tools for businesses across packaging, printing, textiles, and industrial applications. As technology continues to evolve, these machines will not only improve production efficiency but also contribute to more sustainable and innovative manufacturing practices.